Truss-Type Hydraulic Jacking Work Platform

Thermal Power Plant Cooling Towers

Exclusively Designed for Thermal Power Plant Cooling Towers

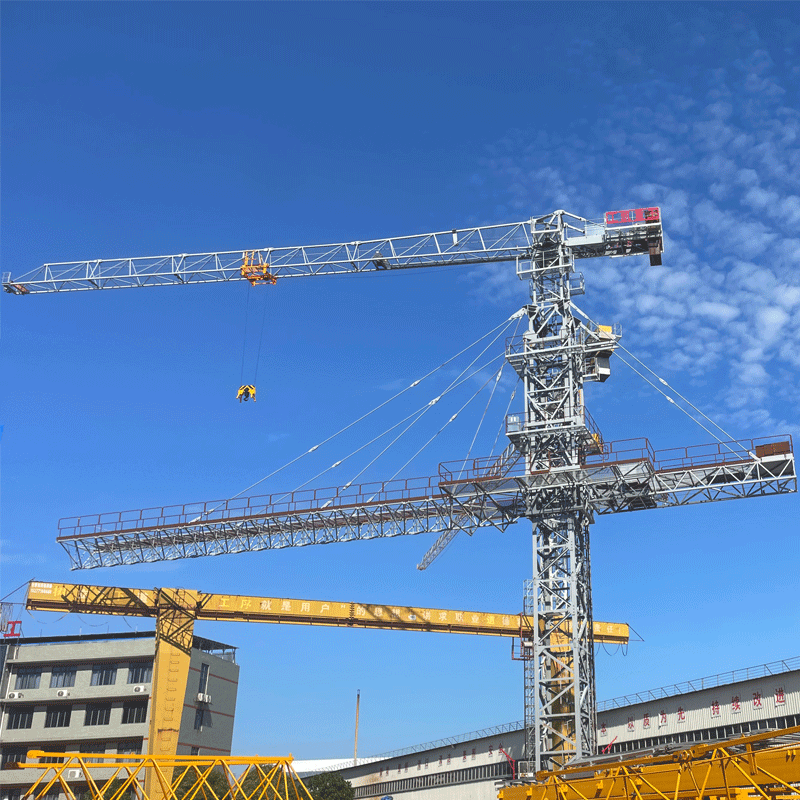

Addressing diverse construction demands across the building industry, GK Heavy Industries has independently developed a truss-type hydraulic jacking work platform. Integrating lightweight design with high-strength performance, it overcomes limitations of traditional construction equipment, delivering safer, more efficient, and more convenient solutions for elevated operations.

Core Scenario: Large Hyperbolic Cooling Tower Shell at Thermal Power Plant Cast-in-place concrete construction serves as the core equipment system.

(1) Core Tower Shell Pouring: An integrated aerial factory platform carries workers, formwork, rebar, and equipment, ascending section by section along the tower wall to achieve continuous cyclic pouring of the shell;

(2)Multifunctional Operation Platform: One-stop solution for formwork installation/removal/cleaning, rebar tying, concrete pouring and curing;

(3) Material Transfer Hub: Features dedicated storage zones for efficient transportation of materials like rebar and formwork, plus small tools;

(4) Comprehensive Safety Barrier: Functions as a giant “safety net,”eliminating falling objects and safeguarding the safety of the work area below.

Compared to universal platforms, cooling tower systems gain a distinct competitive edge through dedicated design.

【Safety Innovation】

(1) Revolutionizing Work Methods: Eliminating traditional suspended high-risk operations,enabling ground-level safe construction and significantly reducing fall hazards;

(2) Comprehensive Protection Upgrade: Fully enclosed platforms function as“mobile protective shells,”safeguarding both personnel and internal equipment from all angles;

(3) Extreme Environment Adaptability: Secure multi-point connections to tower walls ensure outstanding wind resistance,guaranteeing equipment and structural safety during severe weather.

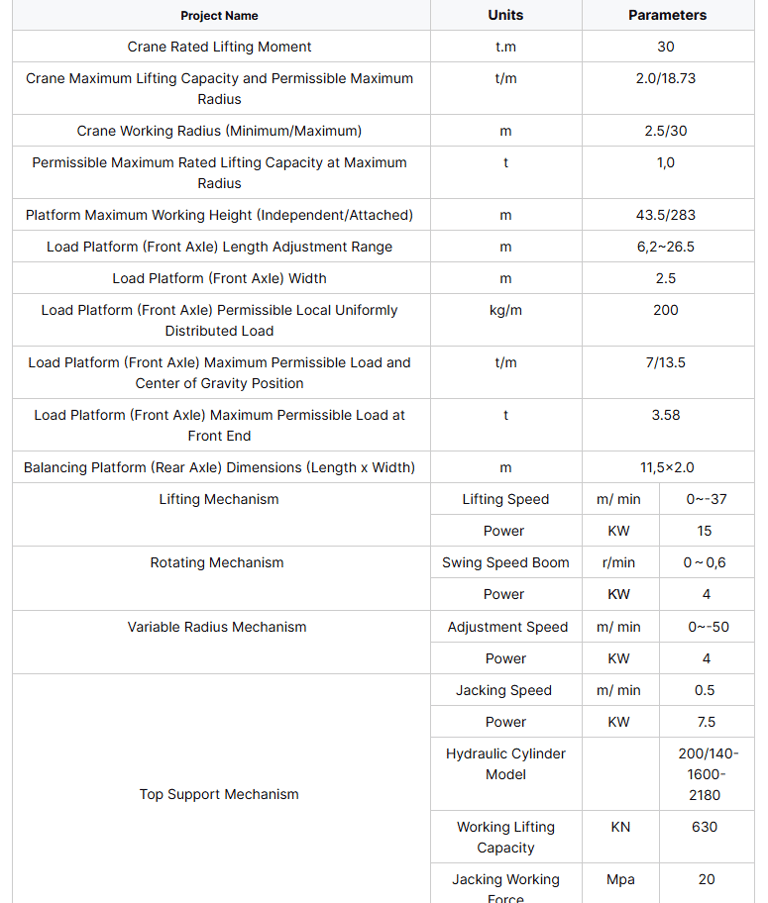

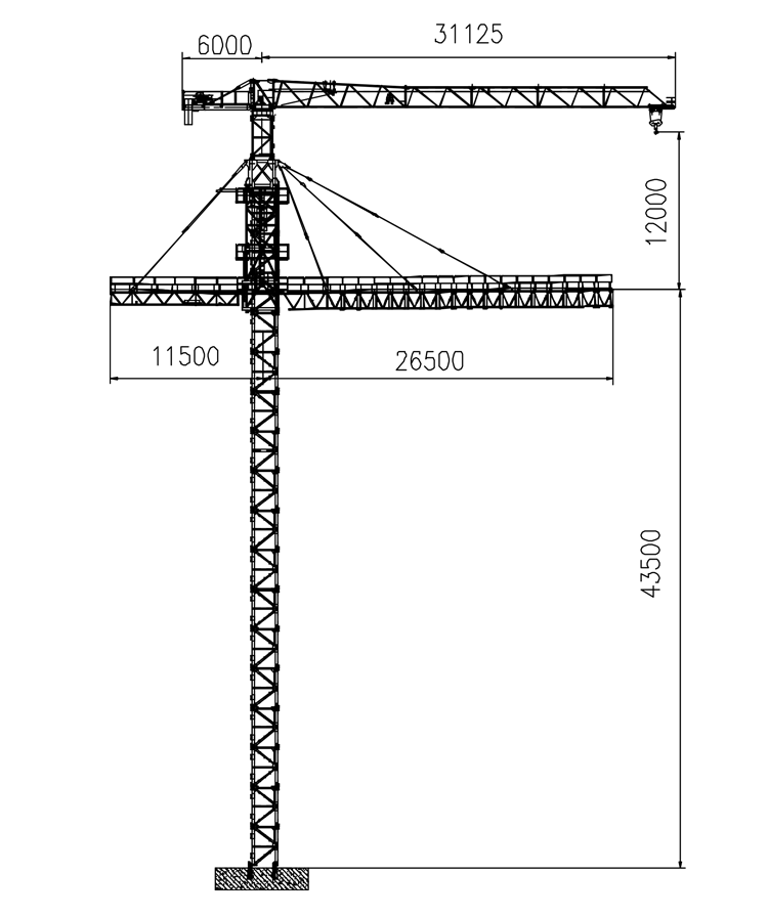

The Shape Size

【Double Excellence in Efficiency and Quality】

(1) Doubled Construction Efficiency: Creating an “aerial assembly line”enables three-dimensional flow operations for formwork installation/removal, rebar tying, and concrete pouring. With a stable daily climb of 3-6 meters, tower construction over 100 meters can be completed within months, significantly shortening project timelines compared to traditional methods.

(2) Unparalleled Construction Quality: Rigid structure + synchronized jacking technology precisely controls double-curved cylinder wall dimensions and surface smoothness, eliminating formwork deformation. Large steel formwork paired with stable support ensures smooth, dense concrete surfaces with uniform color. Continuous construction minimizes construction joints, enhancing the structural integrity of the cylinder.

【Multi-Dimensional Value Empowerment】 (1) Cost Optimization: Eliminating tall scaffolding significantly reduces material, labor, and schedule costs;

(2) Labor Efficiency Enhancement: Mechanization and automation upgrades reduce high-altitude labor requirements while improving resource allocation efficiency;

(3) Enhanced Comprehensive Benefits: One-time investment yields long-term returns through accelerated project timelines, enhanced safety, and improved quality, substantially reducing overall project costs;

(4) Model for Civilized Construction: Centralized material storage maintains tidy, orderly sites while minimizing land occupation;

(5) Green Construction Compatibility: Enclosed platforms collect construction debris, preventing high-altitude pollutant dispersion and aligning with modern environmental standards.

Request a Quote

Connect

Get in touch for your project needs today.

Contact us

Email:ann@gkzgtowercrane.com

Tel/Whatsapp/Wechat:+86 13437895301

Copyright © 2025. Guangxi Gongkai Heavy Industry Manufacturing Co.,Ltd.All Right Reserved

Address: No.12 Fuqiao Avenue, Longan Overseas Chinese Administration District, Nanning, Guangxi,China